Got a chance to meander, so I am. Ill be back prolly 1 Jan or so.

Wednesday, December 28, 2022

Sunday, December 25, 2022

Happy Christmas!!!!

Saturday, December 24, 2022

Story Time Christmas Edition

I got invited to a candle light service today. I went and it was a very nice time. Got to eat at someone else's house, too. Great conversation and fellowship. I just about got hypoxic. There is a definite limit to how much I can talk and laugh now. I almost turned into a pict.

But the candle lighting reminded me of a great Christmas story from my youth....

I met this cat name Deberry in eighth grade. He wasn't a very big guy, but his wit was huge. He was the type that funny stuff just swirled around him like millers around a porch light. Think mid 1970's.

He was talking about a candle light service at the First Baptist Church a year or two before. Almost every Southern Baptist Church had the same general layout. Like

the soviet gulags, the floor plans were in a big book of standard facilities for

different size populations. This "youth room" had the accordion room divider and the

gray tiles on the floor. Gobs of those gray metal folding chairs in rows, too.

Seems this big kid was bugging him. Manhandling him, pushing him, hitting him and generally being a jerk. So the youth director settles everyone down and hands out the unlit candles.

They sang Christmas carols and had Bible passage readings. The lights were lowered and each kid would light their candle from the kid next to them, and say a prayer (free style praying, no rote memory in the SBC). The next kid would light his candle, and it went across the front row and then looped around to the back row. As the candle lighting got close to Deberry, he closed his eyes. *BANG*, the jerk in the front row slapped him upside the head. It was dark, everyone heard it but no one saw it. So, they just carried on. When Deberry lit his candle he had this thought wash over him. He extended his arm and put the candle just under the hair of the jerk.

There was a flash of light in the darkness, then FOOM! WHOOOSH! the fire ran up his head fast as lightning! Deberry reacted like we all would, he unloaded a slap and hit the jerk right above the ear, trying to put out the fire. The jerk sprawls out and hits those metal chairs. The noise is unmistakable as they skid all over the floor. Then the thud as he falls over and the "UHHHhhh" as the wind is knocked out of him. He is sitting there, spradle legged, with his hair smoldering...

Without missing a beat, Deberry says "AMEN", then turns to light the other kids candle.

I thought about that right in the middle of the candle light service. It was all I could do not to laugh out loud. I haven't thought about that story for forty years or more. What the heck!

Chuck

Got the chuck rubbed down some. Lathe chuck jaws needed to be reversed first to hold the smaller chuck body, then, used a bit of sandpaper on a stick to rub the spigot down so the scroll fits semi-perfectly.

Handling 20 degree metal sure pulls a lot of heat out of you. My hands took several minutes to warm back up. Dang.

75 degrees and humid next week, so everything metal will sweat like a glass of iced tea. I gotta paint the tools up with some oil to be sure they don't start to rust. Such is winter in south Texas.

|

| Needs another bath now |

The heaters are running, got some quiet Christmas music playing in the background. Dog is curled up on the carpet, and I'm close to calling it a night. It's cold and clear outside, just like a Christmas eve should be. I'm wore out and ready for a nap.

Happy Christmas to you and I hope you get what you want, and not what you deserve. Unless you still burn coal, then a whole truckload would be great.

Friday, December 23, 2022

Planning

I gotta have a plan. I really need direction. I don't 'exist' very well at all. I have an engine in my head that can't let me just sit and rest. At least, not without tremendous guilt and self-berating. Gotta figure out what to do and get it done. It's always been that way.

So, tomorrow is shop day, I hope. I have that chuck to finish up. Then there is the dividing head to finish cleaning as well. After that....

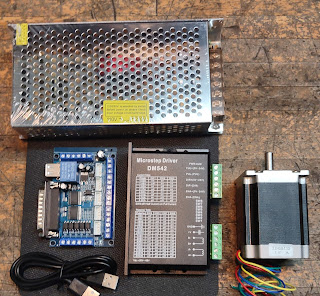

I've got to get this lot wired and work out an attachment for the dividing head. I've got a wacky idea for LinuxCNC on one of the ancient abacus based laptops I have. I didn't buy the dividing head to do this, but it sort of popped up shortly after. I wonder if I can duplicate a universal head with this setup?

I still have the two casting kits as well. Important family issues jumped to the head of the line. Almost complete with those. But it's getting close to time for these projects to come back up.

I posted a bit of personal thoughts below the fold. Sit in the parlor and visit if you want.

Weary, but not Frizzed

Got the holes boarded up. Just. Ran outta steam about halfway through. I used to have a granny gear. When I got too tired to go much farther, I could put it in low range and just plow on through. I don't have that anymore. And trying is a sure way to go down for a week. I found that out earlier this year.

So yesterday, I got the last bit on the north side covered, then went after the south side. Plumbing for the tub was on that side. Made some insulation for the pipe coming out of the ground. Got the siding hole covered, but had dug a hole so I could get under the sill plate. I didn't want to fill it just to dig it out again, so I got a leaf bag and cut some of that tall grass around the fence. Filled the bag up and rolled it into the hole. That'll keep the wind out. Thought about that plexiglass window on the east side bedroom. Looked at it, and just as I touched it, it fell out of the frame. Not the day for a pneumonia hole. Found some foil backed foam board leftovers and made a window pane. It worked well last night.

Figured to do the same grass bag insulation with the hose bib out front. Got that done, when the clouds blew south and the sun beat down. Very nice and warm, if a bit humid.

There were multiple rest breaks, but I beat the weather. After the winterizing was done, I started working on trailer lights for the yard art. Don't ask why, I just started in and that went quick and easy. Then, "why not move it to the other side of the yard? I can finish the wiring over on the flat spot with the sun on me? " THAT just about ended me. Brother, that little trailer is nose heavy. But it's moved. Wind shifted about a quarter after 3. It got cold quickly. I had the

doors open to air out the place, but that didn't last long at all. Almost 60 to 32 in a couple hours. Down here, that's fast. Up in Lubbock county, that is very slow. Temp drops of 40 to 50 degrees in an hour are not uncommon up in the panhandle.

Today, I'm gonna do some house work that's been waiting for a few weeks. Maybe even make some cookies. Good baking weather.

With all that snow on it, it reminded me of my old 1974 Plymouth Fury. I got all homesick. I do miss that car. She was fast and agile. I learned a lot of good things in her. Power slides, reverse 180, fishtailing, flat track turns, J turn... the proper way to float over RR tracks and other lumps in the road. Very little body roll, handled like a go kart.

360 small block, two barrel carb, 727 Torqueflite trans. Speed rated police tires, and those little hub caps. Very neat car. I have always regretted not fixing it after the accident. I know how, now. Such is life.

Happy Christmas!

Thursday, December 22, 2022

Winter Preps for the Infirm

Been trying to get ahead of this winter storm. I pulled siding off a while back to work on the plumbing. I got a bit left to replace and fix today. It's been slow going. I can do about a good hours work a day, an hours worth of what I used to do. Now it takes all day to get it done. Spurts of 15 minutes or 10 minutes then rest up. I don't get cold much anymore, I'm constantly steaming about the limitations!

I've got a couple hours left to do what I can before the wind kicks up. You would hope, after having raised a family and helped out however and where ever you could, someone would help you out... hmmmm..... I guess not.

Off to the time crunch salt mines....

Take care out there.

Friday, December 16, 2022

A West Texas Christmas Story

Anyone that grew up on the high plains of West Texas will remember the colors of Christmas: tan, yellow, brown and bright blue skies. The wind was always blowing, and it was usually very cold or quite warm.

.jpg) |

| View across the county road from October to January: cotton modules |

|

| If we were very lucky, we avoided this at Christmas |

|

| Magical winter neighborhood scenery |

We were visiting my suegra (mother in law), and I was out on an errand on Christmas day. I heard the craziest story from a couple of radio personalities.

One of the guys was talking about Christmas day in the 1930's when he was a little guy. He and his brother woke up at the butt crack of dawn. it was really cold in the clapboard house and still dark. They ran into the front room and looked under the Christmas stick tree. There were two presents. They couldn't wait, so they ripped them open. He got a pack of fire crackers, and his brother got a rubber kick ball. He said he went to the kitchen and got some matches, and they both went out the front door in a run. He lit the firecrackers and they were crazy loud. It scared his brother and he took off running and tripped on something. He fell on the ball and it popped. Christmas day wasn't even 10 minutes old and they had shot off and broken everything. He remembered being pretty glum the rest of the day.

My dad told me few stories of his youth, but never a thing about a Christmas. I figured his were a lot like that radio guy's. Dad lived on a farm that looked really similar to this.

|

| I saw a pic of my dad when he was a boy in a place just like this. No green at all, just dirt. |

Happy Christmas.

Wednesday, December 14, 2022

Sunday, December 11, 2022

Interference

I mentioned before the chuck had a tight feel. It took effort to turn the key to tighten the jaws. That's shouldn't happen. All my others are easy to move, so that tells me this one has some issues.

|

| blued |

I marked the inner and outer part of the scroll plate with blue Sharpie, and tapped it lightly, as if I were installing it. Turned the chuck body over and tapped it back out. There is a nice blue line showing where the rub is. Tomorrow, I'll work on the fit. I'll have to go to my "ask a friend" card and see what he says is the best way to approach this. It's not a rocket surgeon's part, but I don't want to make scrap either.

|

| right below the threaded hole |

Saturday, December 10, 2022

Bath Time

Time to clean the chuck. It was dirty and nasty. Lots of grit and grease. I pulled down the new ultrasonic cleaner. Didn't find any Zep505, so I used Dawn dish washing liquid. A bit of hot water, too. After pulling them out of the hot water, and wiping them down, I shot some oil on them.

Two uh oh's:

The chuck came out with some stains. I figure I soaked out some grease or oil, and it took root in the polished part of the chuck. I can live with stains, but that is some strange stuff. Weirdness...

Second uh oh was a bit of surprise.

|

| Right along the unmachined circumference, there is a wire edge. |

|

| Looks like a hair, but it's as sharp as a razor. |

I guess this is one of the reasons you want / need to take these things apart. You never know how the QA department is getting along at the manufacturer. That thing would eventually get loose, and might work itself out... or with my luck, into mischief or my finger.

The file just skated off the scroll. It's hard. Just like it should be. I used a diamond hone on it.

The third uh oh was the middle spigot of the chuck body isn't concentric. The middle of the scroll binds when you try and reassemble. This explains the tight operation of the chuck. I will have to fix that too.

It's a kit, all the parts are here, it needs work to be a complete tool. But we knew that....

Or, you can buy one of these from Logan Actuator Company:

|

| No doubt about it's quality at all! |

😲

Friday, December 9, 2022

Thread Gauge?

I decided to make a little "thread gauge" out of the back plate "handle" I made yesterday. It looks pretty cool doesn't it?

| |

| No chatter on the threads, some tearing on the face cut |

I really do like that lathe. And those knurls are sharp. They really grip right back. I need to work it over a little with a file. I does have a few spots that might get a little too close to you.

What do you think?

Shop Made Tools

The back plate on the new dividing head is stated as 1 1//2" - 8 thread. I decided I needed to make a stub to hold it. My stub thread is 1.484" in diameter, the thread on the head is 1.494" I missed the pitch diameter for a 2B thread by -0.002". I figure that's pretty good, since I haven't single point threaded anything for quite some time. This shaft threads into the chuck back plate about three threads deep. I was going to use it as a way to remove the chuck off the plate. It's pretty tightly on there. The raised boss on the plate is a press fit on the chuck body I guess.

Instead of striking the stub, I'll unscrew the three cap screws a quarter turn and tap on them to release the chuck. Then, I'll thread some holes in the back plate to push the chuck off next time.

I left the screws a little loose, then tapped them with the brass hammer. it popped the chuck off quickly and easily. Now to disassemble and clean it. It seems very tight compared to my other ones.

That Sheldon lathe is rigid and powerful. It walked through that 1 5/8" steel rod like it was nothing. Only took slightly more than an hour to make that part. I'm impressed with it yet again. And the lard based cutting oil leaves such a nice finish, it's worth the added mess. Smells weird when it smokes, but I can live with that (I hope).

|

| no chatter |

I was starting to believe I was just a piker at best. But you can buy better accuracy and finish. I was past using the LeBlond, I need the Sheldon to make quality parts. Graduation present? Not tooting my own tooter, but I think I have gained some skill since I first started. I envied the work that Spartan, Mr. Pete and others can do. A quality tool makes the difference. I don't have the experience to fix a really bad machine to make quality yet. Maybe there is time to learn that too.

Observation: Society

I had to go to the Beg City two days in a row this week. We are doomed. I used to drive there every day. I either have gotten waaaay out of practice or drivers are worse now. There is wholesale "me-first" on the highways. Multiple accidents kept me in town for nearly an hour more than needed as I navigated to get O-U-T.

Cutting into slow exit lines was always a thing, but the reckless abandon now is a bit frightening, and new to me.

The swerving into and out of traffic only happened occasionally, but it was every where this last week.

I didn't get there too early either time so it wasn't the rush hour. Crazy times. Should I make a ram for the front of the truck, maybe hang some old tires around the sides like a tug boat, and put a long spike on the back?? Maybe folks would stay away if I looked like a horned caterpillar.

Monday, December 5, 2022

Stuck Chuck

I started making the little pins I'd figured on, and they didn't work out too well. So, scratch that and *hmmm, why not use something you already have? Like a dull drill bit for the pin?*

Hardly any digging and I had what I needed. pinned the two holes, added some paper scratch protection to the sides of the head. Mounted to the mill table, and it popped off with a little effort.

|

| It's getting lighter... |

Next up is to strip it of the parts and pieces, clean, oil and reassemble. The old super maxi ultrasonic cleaner will be put to work, if only to justify it's existence. One thing that is really important is the depthing adjustment of the worm gear. On the right side of the above picture is this "screw".

|

| Depth adjustment on the right, lock screw in the hole on the left |

I have to get that back right, so now I have a documented position to return to. Internet can be helpful.

Next up is pulling the spindle-bearing pack. I'll need a pin spanner for that. This is the nut that has to be removed from the back in order to drive the pack out the front.

| |

| the nut has two holes for pins, and the screw locks it in place |

I've seen pin spanners that look like dividers. Super neat. But in a pinch, you can use a modified All-16ths wrench. Drill two holes, add pins, and Viola, instant adjustable pin spanner. I think I have a cheap-o that would be a prime candidate for this. That's the next step.

|

| drill two holes add pins |

One other thing I need to do is get a project pan for it. They sell blems at the restaurant supply for $4.00. Probably more now, but they are available locally really cheap. Heavy duty for industrial baking.

|

| sandwich bags keep assemblies together |

And I remembered to mark the chuck, jaws and back plate so I can reassemble it like it came to me.

|

| I should make an etcher |

So far so good. I usually go too far too fast. I'm taking this little cleaning project slow and steady.

Sunday, December 4, 2022

Tool Pron

Brown and Sharpe 0 Dividing Head

I finally saved up for one of these. And it's here. The BS-0 dividing head. These are so useful for creating gears, flutes and splines. I found an old one at the Rodent Urinal and Machine Shop years ago. It was beat on, and rusty and I could never get it to work. So I got this one.

|

| This is on Ebay, same model and manufacturer |

Now, a well known issue is the unit is full of chips and grit from manufacturing. Mine has a very stiff chuck. I reckon it's just like every other one out there. Double plus ungood is the back plate is so tight, there isn't an easy way to remove it. This 'tuber had that issue.

He didn't detail how he did it. Just said a spanner and an impact. I don't want to break anything so I'm working on a brake I can make with pins that goes along side of the housing and catches two of the holes in the direct indexing plate. I thought about catching only one hole in the plate, but I don't know if it will be strong enough to hold against the torque.

| |

| Those two, or the one in the middle? hmmmmm..... |

Had to do some measuring to see what I need to make. And I came up with this on my thinking pad.

I really don't know how close the two holes are to the flat side of the body of this thing. So, I need to make two pointy bits to fit into the marked holes and make a scratch on a rectangular piece of steel. Then, I can make the proper placed and sized holes to slip the pins in and hold the spindle from turning. Maybe I can chuck up some hex and use it like a bolt head to try and removed the chuck and plate.

There is another owner down in Austrailia that showed pulling his apart, and the bearing on it was gritty. He made some additional parts and got a new bearing for it. He also made a pin spanner for the back nut. That was pretty wizard.

All Bundy Bears Shed videos about the dividing head are real time. He doesn't speed anything up that I remember. He shows some detailed lathe work making the parts he wanted.

I need to quit putting things ahead of the pantograph. I got the itch to get that done, other things seem to pop up as well, but they don't scratch the pantograph itch. Not by a long shot.

Saturday, December 3, 2022

I'm Officially Confused

Is this a "lost in translation" issue? Am I missing something?

Perhaps a petite E-normus?

Does the Titan come in small or medium?

Mind Boggle....