Family member is doing better, but I was worn to a nub from all the watchfulness and work to keep them safe from themselves.

Then, I started to sag. Sneezing, the constant flop of temperature, humidity and barometric pressure was starting a packed sinus that would wind up in an infection. It was dragging me under....

THEN.... my sister told me about something she made. She brought a tiny bit by the house and I tried it.

Play by play:

1 - tasted really good, and felt good the second I swished it around in my mouth.

2 - felt good when it hit my stomach. An odd feeling to say the least

3 - was kind of rude, in that it pushed everything ahead of it out, mo ricky tick.

4 - sinus pressure began to decrease, and drainage picked up.

5 - Overnight, sinuses started to work like normal. Lots of leftovers in the morning kleenex, but I could smell again!

6 - No sneezing, little coughing, and the cough is more productive than it has been since July 2021. What?!?!?!?

7 - You gotta try this stuff.

|

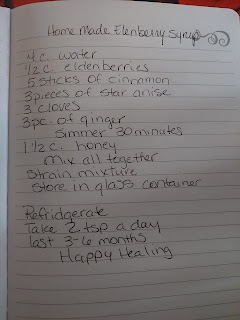

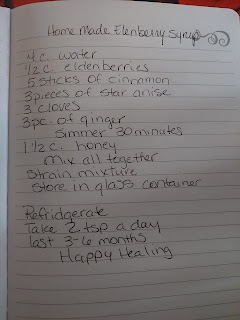

Elderberry Syrup

|

It may mess with medications, so do your diligence on research. I noticed a difference in less than a day. I wasn't doing anything else different. It really seems to work.

.png)