This winter, now that I'm on the mend, I wanted to do some shop

projects. So, I've been reading my books, looking at the net, yadda

yadda.

I've been watching folks build some really cool stuff on the YT. Joe Pie has been doing miniature models, as has Blondiehacks. Spartan-C got a few of those tiny kits for winter work. Windy Hill has been making castings. I started to get a yen for a project for the winter. Our winter is usually like late summer weather for those north of 40° North latitude. Averages around 50-60 at night and 70-85 during the day. Some days it can get colder. But the La Nina holds up the temps. The gulf also moderates our temps.

So, I was reading Workshop Techniques, and I ran across a couple neat projects. G. H. Thomas outlines a small pantograph machine. I have some of those old K&E lettering templates, and I thought, why not. I have a few drachma saved up. It would be kinda cool to be able to engrave stuff with those fancy letters. That started an internet hunt for any casting kits for it, and I finally found Martin Model.

I got the last one!! Very quickly shipped and every part was wrapped in paper. Even sent along some C size drawings for machining and assembly! The castings are top drawer. Fettling wasn't over much, and I didn't see any inclusions or blow holes. Three had cores. Very nicely done.

Back several years ago, my mentor was asked to help liquidate an old machine shop in REDACTED. We went to look, and it was a squirrel and rat restroom. Some windows had blown out, and the critters moved in. The owner had degenerative head disorder, and his daughter had stayed with him to the end. She was the one that requested the help, as it was time to move on. I got a lot of stuff from there, as did my mentor. I paid her probably too decently as I take a dim view of folks taking advantage of those that are easy pickings. My mentor basically priced the big stuff for her, and we picked through the small stuff. One of the things I got was a dividing head.

The dividing head allows you to rotate a work piece precisely. It has a 40:1 gear ratio (some are different 90:1, 30:1, 4:1) , allowing you to divide a 360 degree circle into basically how ever many divisions you want. One crank turn is 9 degrees, a third of a crank turn is 3. It allows you to make some very interesting things. Gears, those cool ports in shotgun barrels, bolt heads, and really, the sky is the limit.

I found one in the shop there, and of course, it was rusty and stuck. I got it for a good deal, and tried my best to free it up and make it useful. Old Hammer Smith, the owner of the shop, had beaten it bloody. It was missing parts of the casting where it had been "adjusted" with a ball peen hammer. I never got it to work. I still have it though, natch. Bound to be some goodies in it I can use. Like the worm and gear.

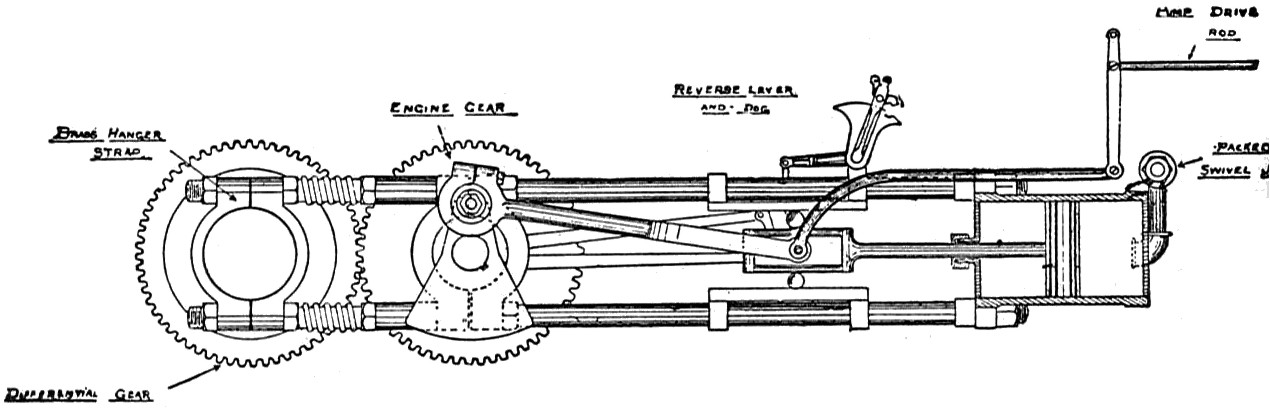

In the same book, G H Thomas shows a neat little Versatile Dividing Head. Martin Model had it, so I bought it. I'm missing a part, so hopefully, that will be on it's merry way soon.

| |

| parts 1 and 3 |

No nifty print for this, I'll have to use the book. This isn't the only place to get one either. Hemingway Kits in the UK has it too. Its the whole package, all the bits and bobs. And it's a sight more coin as well. Plus shipping across the waters.

So, there are options.

Personal Updates:

The big D is on again, and it keeps getting changed. I'm ready to be done with it. Just flat done.

Youngest son's trailer house sprung a water leak. I fixed the worst ones, and then it blew out again. Just got done today with the second fix. Me and my sister in law, the sister of Herself, worked it through and finished it. She's a hoot. We allus have fun working together. She's about 5 years younger than me. And I've known her longer than Herself. I..... dunno what I was thinking...

Wriggling under a trailer house and connecting PEX wore me out. I worked a grand total of 23.2 minutes over a four hour period and I am d-u-n, done. The up and down on my knees eats through my stamina fast. But I always feel better after I rest a couple days. And I seem to last a little longer each time I work out. And by a little, I mean 5 minutes or so. Not very much at all.

Thanks for stopping by. These days are flying by. 17 since the last update? Rilly?