Note: a drill press is not a precision machine. I need to get the old high speed drill on the bench and sorted.

So one hole worked out okay, but was a bit high, over the line. So I faced off the extra on the lathe, and tested the micrometer spindle, a few times until it worked.

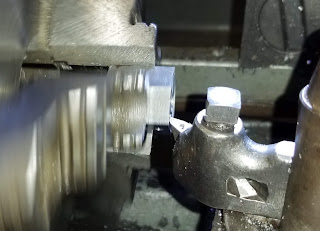

#44 drill bit, lathe in back gears, and it spun off like silk. Now they need a cleaning and a good soak in the de-rust-it. Then over to the super penetrating oil.

|

| Where we are now |

|

| Trying to get to this point |

Wonder how much I have in these 14 dollar mics now?

"Wonder how much I have in these 14 dollar mics now? "

ReplyDeleteLol, that consideration went out the window long ago.

Now it's personal.

Sounds like you are slowly making headway in the healing department and I am glad to see it.

Thanks for stopping by Phil! Yeah, I'd like to get these running at 100%.

DeleteI have had 3 good days in a row. Here's hoping that the rest of my "vacation" is enough to allow me to get back to work. 3 weeks into this now.

I'm taking the machining slow and easy. Just like when I used to do tower work. Deliberate, slow, thought out movements. I don't want to do something stupid and get laid up again!!

I appreciate your encouragement. And it has been and still is slow, but hopefully steady.

"I'm going to add this set of wheels I have sitting around to the miter saw stand to make it more portable, and it won't cost anything." (me)

ReplyDeleteSo far I've spent north of thirty dollars and I'm not much closer than I was when I started.

What Phil said about it being personal is exactly correct.

Everything seems to take a bit more than first thought. I don't know why, but that is the deal.

ReplyDeleteAnd I agree, it is personal. I want to get these running nicely, and not quit. Thanks for dropping by.