John in Philly is killing me. His puns are loaded and ready. He got me with "Chuck Roast" in the comments. It's a groaner, but I laughed anyway.

Cleaning ye olde Polish chuck went smoothly so far. I sprayed some of the leftover grease off with brake cleaner, then put the parts in a bucket with Zep 505 and poured in boiling water. It was nearly 80 degrees outside so, the total temp change on the chuck was about 135 degrees. We are aboot 400' ASL, so I don't derate the boiling temp of water because the pressure isn't quite 1 Bar.

Okay, I had to find out: water boils at 211.3° F at 400 feet, 80° F ambient air temp, standard pressure.

Hot water rinse after tooth brushing them. Wiped the parts down with paper towels and put on some spray Rem Oil. I found that oil really cheap a year or so ago. Didn't want any flash rust or GREASE!

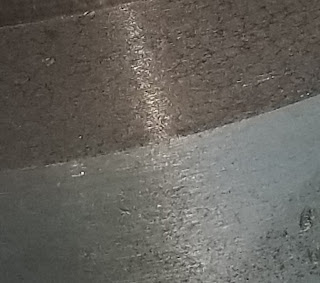

I decided to run a little diamond hone around the razor edge of the chuck. I did two swipes on three angles using the backing holes as distance markers. 6 total swipes. I just broke the edge a touch so, no more skinned hands.

|

| Razor sharp edge! No radius or chamfer!! 90 degree angle between the dark and light gray. |

|

| Cheapo that I keep in my pocket |

|

| angle 1 |

| |

| angle 2 |

|

| angle 3 |

|

| Nice little 3 angle chamfer to keep the mitts from bleeding. |

I still need to clean the pinions, the jaws and hardware. I also need to dig up another cap screw for the backing plate. Then, it'll be on to tearing apart the mail order quick change gear box to make the lathe ready to use again.

Personal update:

I got an email from a buddy at the main campus of the old job. He mentioned a desk job that is unfilled. Hard time finding anyone to do it. I asked him to sound out the manager, so he asked about it, since I can't login to our corp stuff (I have a feeling they do that so you are worthless when you return. I'm totally out of date on my old job, so much has changed.) He sent me the boss' email.

I shot over an introduction, and dropped two names he would know. He shot one right back. "I know you!" That was kinda cool. Call tomorrow to discuss the job and see if I can / should apply for it. It's like a technical writing position on some systems I used to support on the dirty hands side of the phone. Not altogether unfamiliar.

If you are a praying man, please do. This was just a bolt from the blue. I have to pursue it, might be a heavenly gift.

STxAR, I think I understood about 75% of the machining post today. Look at me, I am learning!

ReplyDeleteThe personal news is wonderful. Definitely Prayers Up!

Cool! You'll be making swarf before you know it!

DeleteAnd thank you!!

Networking! The only way to succeed based upon your qualifications and knowledge. Avoid the HR department at all costs!

ReplyDeleteYes sir!!! I worked hard not to burn bridges over there. I'm hopeful!

ReplyDeleteI'm praying for you buddy.

ReplyDeleteI sure do appreciate it brother! If this is a fit, I don't want to miss it.

DeleteYou betcha, STAR!

ReplyDeleteBest of luck! 😉👍

What a man!!! Thank you!

DeleteThat's great news....we'll do our best with the Santeria from this end.

ReplyDeleteYIKES!!!!!

DeleteI'm doing my best here.... ;-)

Deletehttps://babalublog.com/wpr/wp-content/uploads/2013/12/PHO-10Jul09-2370981.jpg

Awesome tan man! Is she pulling you out of a smoker???? You are rocking that mustachioed, cigar smoking holy man vide! Well done!!!

DeleteI'm glad my pun made you, savor the moment, chuckle. :)

ReplyDeleteI wonder how much power you would need to fire up an ultrasonic cleaner big enough for a large lathe chuck.

Fingers crossed about the news.

Yes sir, I had a big CHUCK-ELL..... hyuk,hyuk..... ;)

DeleteUnfortunately, it's not a remote position. So, I can't apply. But that isn't bad news per se. It isn't a do or die proposition right now. Thank God.

for sharing thank you for this information this blog is very helpful, I learned very much.

ReplyDeleteInstagram bellen